Annual Maintenance

Our Principle activity is to undertake Annual Maintenance Contract of any capacity & Capability and the same is supported by very Qualified and Experience Staffs, Engineers and Technicians. This facilicity services is on the basis of 24 hours on call.

Annual Maintenance Servicing & Testing with 4 quarterly visits consist of The following:

| S.No. | DISCRIPTION | QTY |

|---|---|---|

| 1 | Service & Testing of Control Panel | -- |

| 2 | Service & Testing of Smoke detector | -- |

| 3 | Service & Testing of Heat Detectors ang & Testing of Break Glass | -- |

| 4 | Service & Testing of Fire Alarm Bell/Sounder | -- |

| 5 | Service & Testing of Fire Extinguishers Dry Powder/C02 | -- |

| 6 | Service & Testing of Fire Hose reel | -- |

| 7 | Service & Testing of Emergency light & Exit light | -- |

| 8 | Service & Testing of Fire Pump | -- |

| 9 | Service & Testing of Sprinkler | -- |

| 10 | Service & Testing of Central Battery System | -- |

| 11 | Service & Testing of Heat Detectors | -- |

- Fire Alarm System Control Panel will be checked & all the functions will be tested.

- Smoke & Heat Detectors. Manual Call Points & Fire Alarms will be cleaned and tested if required.

- Smoke Detectors tested by aerosol spray tester.

- Software expenses including hardware items are beyond the scope of maintenance contract and to be met by client. However, EVERSAFE will provide all support to rectify such troubles.

- Any items are to be changed in Fire Alarm System etc. It will be charged extra.

- The Fire Alarm & Fighting System will be maintained on a Quarterly basis and kept in fully operational condition at all times.

- Fire extinguisher testing & servicing free of charge. If any refilling required then it will be charged extra.

- Material replacement after your approval at your cost during AMC

- Third party expenses like programming to be met by client.

Scope of work:

Fire Alarm System Maintenance & Certification

Inspection Procedures for Sprinklers.

- Inspect all fire department connections.

- Inspect all flow switches.

- Inspect all control valves and tamper switches.

- Perform a main drain test on all risers noting static and residual water pressure.

- Test alarms on sprinkler systems.

- Inspect all dry pipe valves for proper air pressure, water pressure and priming water level. Trip test once a year.

- Drain all low point drains on dry sprinkler systems.

Verify that the monitoring company receives signal of water flow supervisory devices

Inspection Procedures for Fire alarms.

- Verify alarm initiating and indicating devices are functioning properly.

- Verify system power supplies (including battery backups) are sufficient.

- Clean detectors with compressed air.

- Test functionality of detectors with test smoke.

- Check every pull station in the facility for accessibility.

- Verify points being monitored are correct (if the facility has a remote annunciator).

- Verify signal reached the monitoring company's office (if the system is monitored).

Fire Pumps

A fire pump is a vital part to a sprinkler system's water supply. The pump intake is either connected to the public underground water supply piping, or a static water source (e.g., tank, reservoir, lake). The pump provides water flow at a higher pressure to the sprinkler system risers and hose standpipes

Jockey Pump

A jockey pump is a small pump connected to a fire sprinkler system and is intended to maintain pressure in a fire protection piping system to an artificially high level so that the operation of a single fire sprinkler will cause an appreciable pressure drop which will be easily sensed by the fire pump automatic controller, causing the fire pump to start.

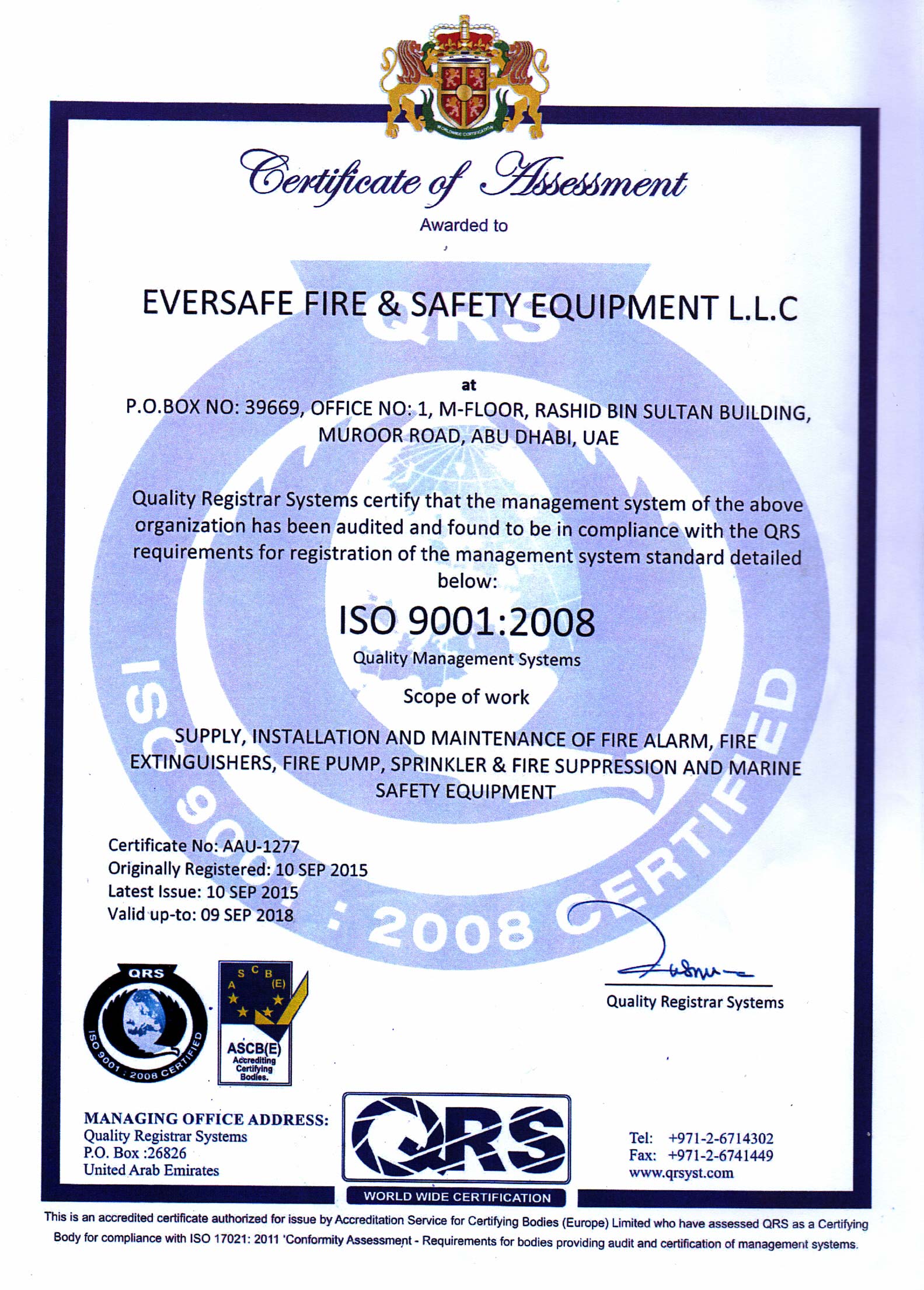

We Are Certified